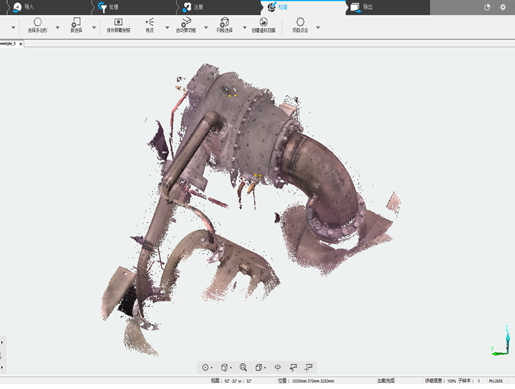

3D Scanning - Smart Factory

- Factory Layout Planning

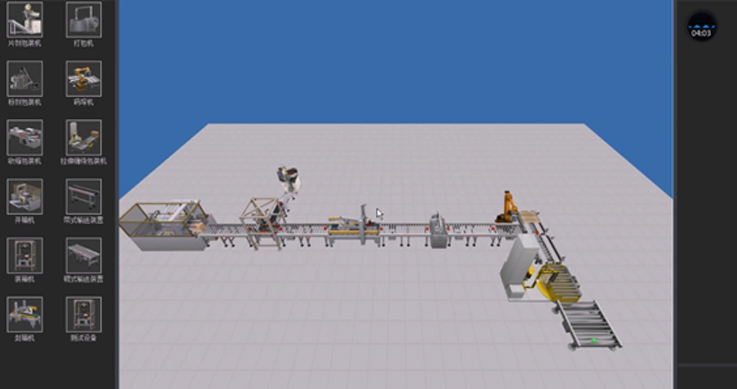

Simulation of Handling and Collision Detection

- Simulation of Handling and Collision Detection

Predict the handling process and detect the reasonable arrangement of handling, machine and equipment operation and production line processing in the factory to avoid collision

- Intelligent Transport Management System

Compare with the rated operating status of the equipment through big data system records, and then manage the health of the equipment

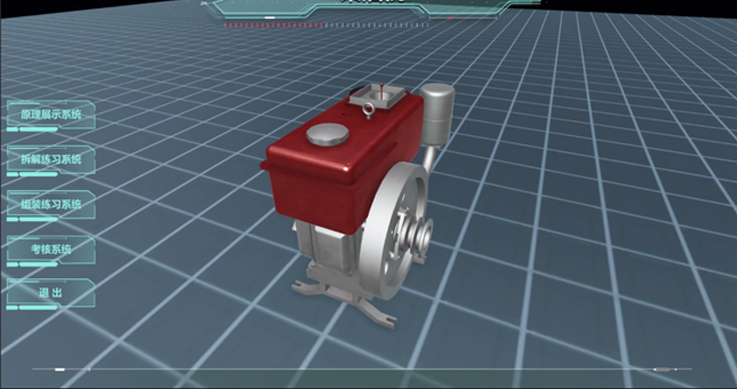

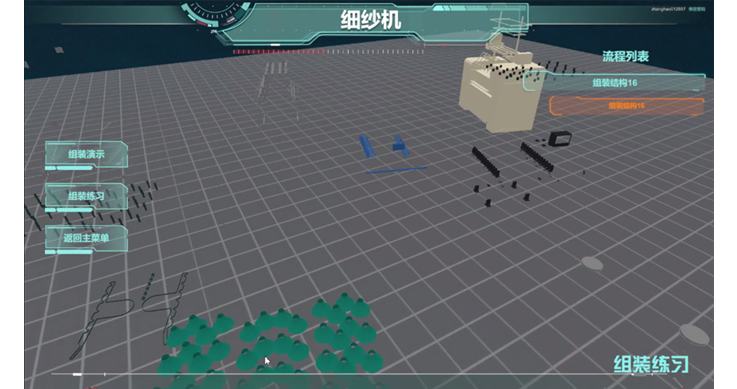

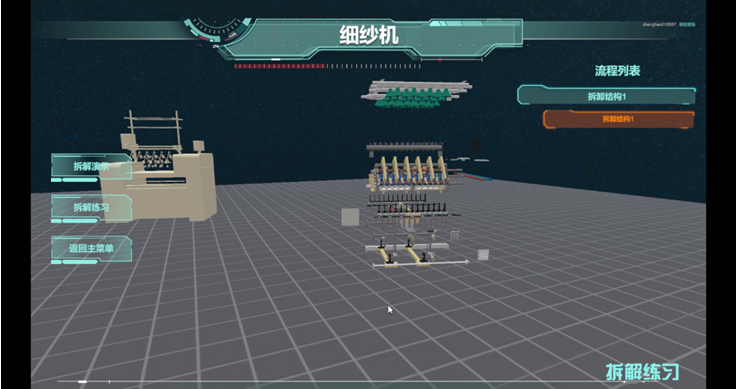

- Virtual Assembly

Test the matchability in advance to find a better solution and avoid losses

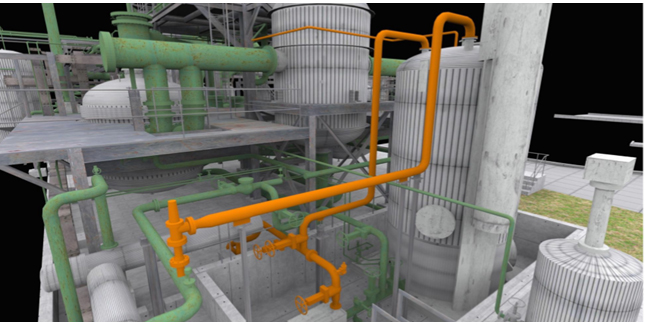

Collision detection, repositioning the exact position of the device .

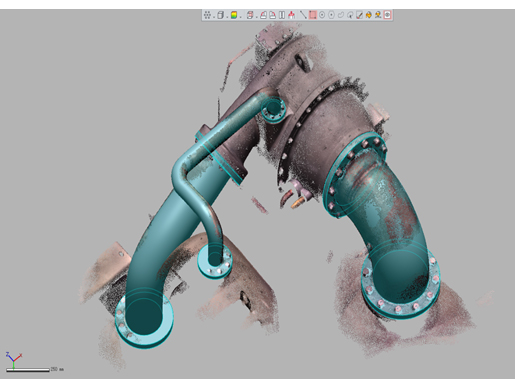

Dynamic and static interference analysis between scanned data, triangular meshes, CAD models and scanned data.

Interference analysis results can be exported to collision point data for applications such as automated equipment pre-installation and handling path planning.

Data acquisition for large equipment, reverse engineering and then doing motion simulation

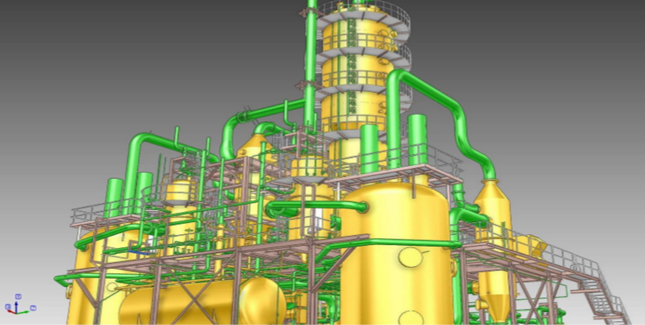

- By modeling the plant physically and developing a visual interface to form a visual plant model, we provide easy and fast services for plant managers to get a good user experience.

- The original scale and state modeling is carried out to provide users with a database model with almost the same accompanying attributes as the original plant, so that users can provide real and reliable data reference for the measurement of pipes and equipment, deformation detection and monitoring, real-time maintenance, equipment renewal, and plant expansion.

- Model attributes include: name, manufacturer, size, installation time, rated life, maintenance information, pressure, temperature, flow direction, and other attribute information.

Intelligent Transport Management System

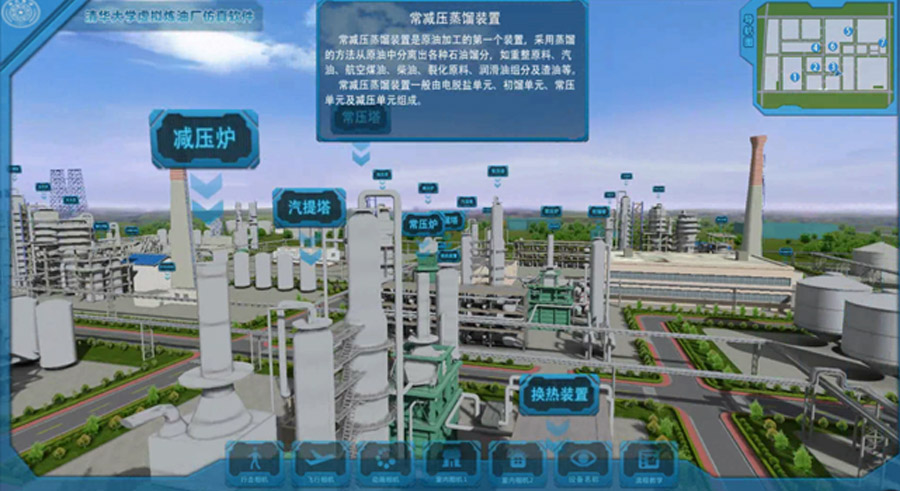

- Virtual Reality

- Simulation of construction

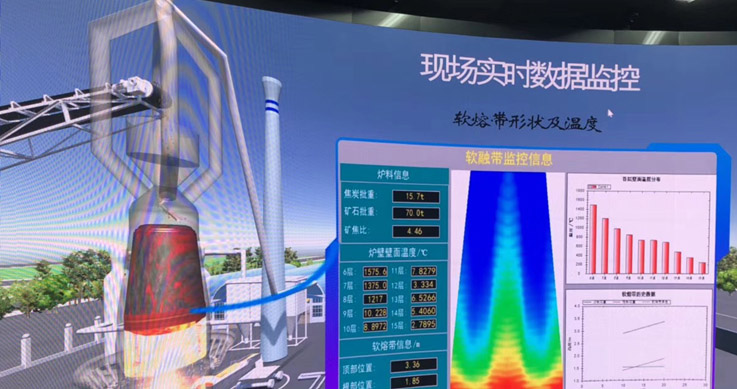

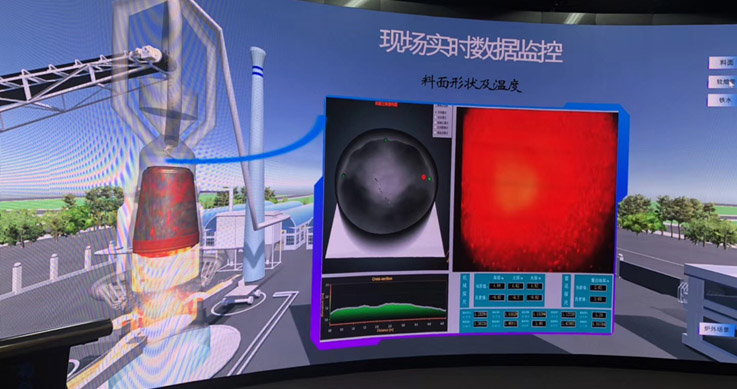

- Real-time monitoring by sensors and cameras, real-time transmission and recording of equipment operating parameters, forming a large database system of equipment operation

- Real-time monitoring: get real-time data through sensors, cameras

- Intelligent management: The management system relies on a three-dimensional intelligent visualization model database to provide users with transparent information about the operation of the equipment, and through the big data system records compared with the rated operating status of the equipment, and then the health management and life cycle prediction of the equipment, such as the actual health status, the performance or decline trajectory of the equipment, when and how the equipment or any component will fail, etc., forming an intelligent and predictable plant management, which in turn reduces operation and maintenance costs and avoids waste as well as some dangers.

Real-time data transmission and monitoring

- Large, intuitive and clear display

- Real-time monitoring: get real-time data through sensors, cameras

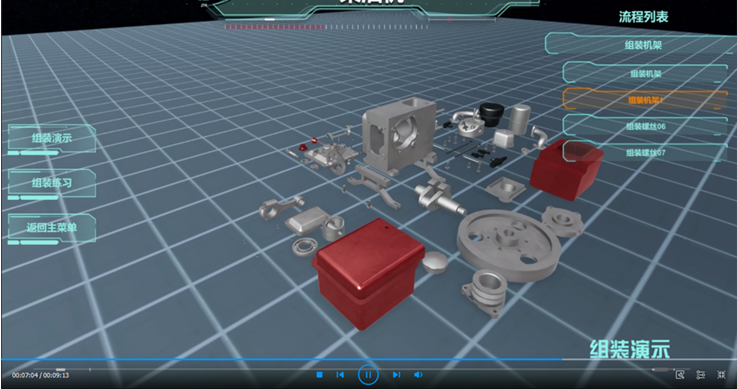

Parts disassembly training and instruction

Exploded diagram assembly disassembly process simulation

Plant simulation, environmental simulation

Production line virtual scheduling

Virtual Assembly

The above is a brief introduction to the application of three-dimensional scanning in factory enterprises, the details and demonstration can scan the QR code below plus customer service to make an appointment to consult.