Industrial Applications

With the development of the modern manufacturing industry, how to shorten the development cycle and quickly and effectively improve production efficiency and quality has become one of the bottlenecks for the rapid development of the manufacturing industry forward. Earlier, the main method used by designers in product design is the forward design method, that is, the idea to the product, but for complex products, the design process is difficult, the cycle is long, and the cost is high, which is not conducive to new product development; the same for product testing, the traditional way is also due to its low efficiency, lack of precision, uneven quality and other disadvantages are restricting the long-term development of enterprises.

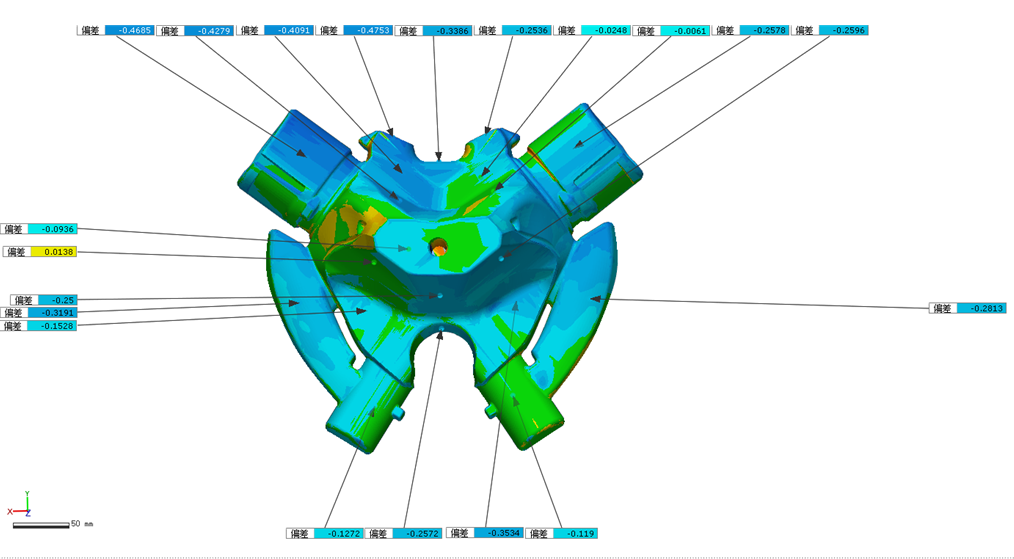

3D scanning technology (including laser scanning technology and structured light scanning technology), as a high-tech developed in recent years, is being widely used in various fields of industrial design and inspection with its characteristics of high precision, high efficiency and real-time. Therefore, combining the technical advantages of 3D scanning and applying it to industrial design and industrial inspection not only greatly improves production efficiency, but also reduces production costs, shortens the design cycle, and largely solves the problems of enterprise quality, efficiency, and product iteration cycle.

Application Scenarios:

New product design development and 3D inspection of parts in the automobile, train, ship, aircraft, machine building, casting industry, pottery industry, etc.

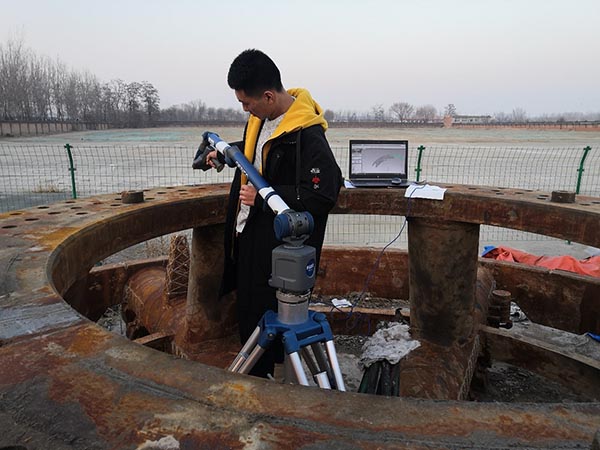

Example of industrial parts scanning: